WORKS - Paper Tube Structures ハノーバー国際博覧会日本館 |

|

|

|

||||

|

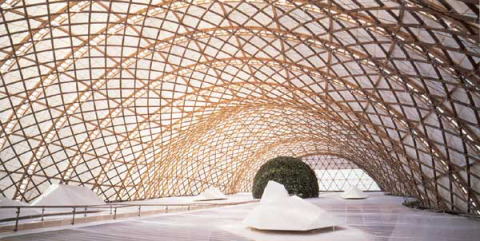

Despite construction problems, the abrupt replacement of the engineer, months long construction delays, and the necessary addition of a PVC membrane over the paper membrane for fire safety issues, the Pavilions has been a great leap forward in the field of paper architecture. The main theme of the Hanover Expo was the environment and the basic concept behind the Japan Pavilion was to create a structure that would produce as little industrial waste as possible when it was dismantled. The goal was either to recycle or reuse almost all of the materials that went into the building. The first structural idea was for a tunnel arch of paper tubes, similar to the Paper Dome. However, the Paper Dome was limited by the high cost of wooden joints. I proposed a grid shell using lengthy paper tubing and without joints to my collaborator, Frei Otto. The tunnel arch would be about 73.8m long, 25m wide, and 15.9m high. The most critical factor was lateral strain along the long side, so instead of a simple arch I chose a grid shell of three-dimensional curved lines with indentations in the height and width directions, which are stronger when it comes to lateral strain. |

|||||

|

|

|||||

|

|

|||||

Another goal was to construct the pavilion using methods that were as low-tech as possible, so they argued for simple joints of fabric or metal tape. As the intersection between two paper tubes was pushed up to form the three-dimensional grid, an angle would open and a suitable amount of tension would be applied. Further, since the paper tubes themselves would rotate to draw a gentle S curve, the joint would allow for three-dimensional movement. Tape was an appropriate solution. Otto also proposed a fixed timber frame of ladder arches and intersecting rafters which would lend strength to the paper-tube grid shell and allow a roof membrane to be attached, and which could also be used during construction and for maintenance. The Buro Happold, who supervised construction, proposed metal joints into which bracing cables would be inserted at a diagonal to tension the paper-tube grid while allowing the paper tubes to move in three dimensions. However, the PVC used in conventional membranes cannot be recycled and gives off dioxins when burned. Then we discovered by chance a waterproof bag used by a delivery service. We talked to the manufacturer of the bag, who told us it might be possible to develop something like what we needed. The two semicircular end walls needed planar strength as diaphragms. For these we used timber arches that clamped the ends of the paper-tube grid shell, and then achieved the required planar strength by pulling cables in a 60-degree from the foundation, as in a tennis racquet. On this surface we attached a grid of paper honey-combs in the shape of equilateral triangles, to which were attached louvers for ventilation and the membrane. Instead of relying on concrete the foundation consists of boxes made of a steel framework and footing boards, which were filled with sand for easy reuse after dismantling.

ハノーバー万国博覧会は、1992年のリオデジャネイロ宣言を受け、環境問題をテーマに掲げている。そこで日本館の設計理念として、博覧会閉会後に解体されるパビリオン自体が問題の環境負担とならぬよう産業廃棄物を最小限に押さえること、そのために建材のリサイクルまたはリユースをデザインのクライテリアとして材料・構造を考えることとした。

メインホール部分は、生産上は長さに制限のない紙管の特性を利用し、ジョイントが少ないグリッドシェル状の紙管アーチを考えた。トンネルアーチはおよそ長さ74m×幅35m高さ16mほどになり、長手の風に有利なように、高さと幅方向に窪みをつけた3次曲線のグリッドシェルとし、内部空間にも変化を持たせた。

紙管同士を固定するジョイントは、布のテープで縛り簡単にジョイントする方法を考案した。このテープジョイントは、地組みされた紙管が押し上げられ、3次元のグリッドシェルになる過程で紙管同士の角度が開くのに伴う三次元的な変位を許容する。またその際に、テープジョイント自体にも適度な緊張がかかり、紙管同士が固定される。

紙管のグリッドシェルには、それ自体に剛性を持たせるために、また屋根の膜材を固定し、建設過程、メインテナンス時においても有効なはしご上のアーチ(ラダー)とそれと直交するラフターという木製のフレームを考案した。

また屋根に仮設で塩ビ膜剤を使用し破棄するとダイオキシンを出すので、強度と防水そして防火性能のバランスを持った、紙膜の開発をした。

基礎は再生困難なコンクリートに頼らず、スチールフレームと足場用板で構成したボックスの中に砂を充填して簡易な基礎を作った。

|