WORKS - Others 羽村の工場 電業社 |

|

|

|

|

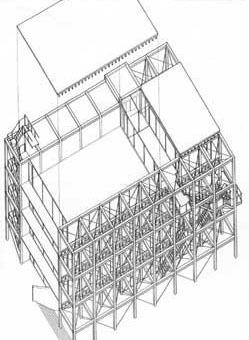

Budget constrains, a short construction period and the requirement for several levels of heavy equipment led us to employ a steel structure with pre-stressed PC boards (DT slabs). First, 4 story steel frames were raised on the East and West sides without any beams to join them at either foundation level or above. The entire horizontal loading on the building is taken through these braced frames which are placed 12 meters apart, supporting the DT slabs on pin joints. Since there are no beams joining the frames it was impossible to position the DT slabs without closing the main road by using a small crane located between the two frames. The slabs were laid in order from the back of the site and the crane backed along the site as each slab was laid. Since the horizontal loads are taken by the frames, the ends could be left open to the fine landscape to the north and south. Furthermore, a highly flexible work space was created. The western frame houses a variety of rooms and machine areas, and the space between the down stands of the DT slabs have been employed where necessary to bring the electrical and air-conditioning pipes into the factory space. The eastern frame contains fiberglass grating and external stairs, and in future small rooms may be slotted into the bays, creating a transitional space between the building and the road. 予算、工期、そして重量機械を多層に設置する条件より、この工場では鉄骨造とプレストレスPC板を併用する構造システムを採っている。東側と西側に基礎にも地上にもつなぎ梁がない4層の鉄骨フレームを建て、全体の水平力をこのフレームにおいて負担し、その上にDTスラブをピン状に置いている。つなぎ梁がないためにフレーム間をクレーンが出入りできるのでDTスラブの設置は楽になり、またブレースなどに邪魔されずに機械の配置換えができるフレキシビリティの高い作業空間ができた。 |

|